This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Used to sterilize

Liquids

(nutrient media, culture media, etc.)

Wastes

(destructive sterilization of liquid wastes in bottles or solid wastes in destruction bags)

Solids

(instruments, pipettes, glassware, etc.)

Biological hazardous substances

in safety laboratories (BSL 1, BSL 2, BSL 3)

An overview of key functions and options

All devices are also available completely in stainless steel design!Contact us

Options for process optimization

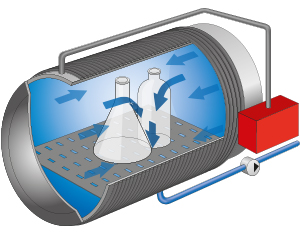

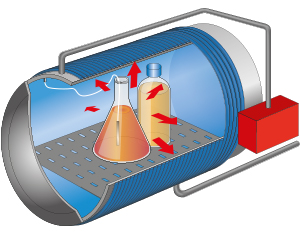

For Sterilizing Liquids

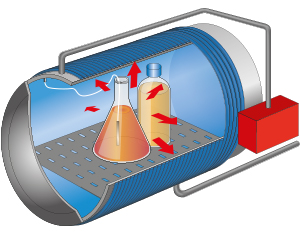

Sheathed cooling using cooling water and support pressure:

During the entire sterilization process, a flexible PT-100 temperature sensor continuously measures the water temperature in a reference vessel. This ensures that the sterilization interval does not start until the sterilization temperature has also been reached in the liquid. The cooling temperature is also continually monitored. The use of support pressure (with sterile filtered compressed air during the cooling phase) reliably prevents the culture media from boiling.

The re-cooling time can then be reduced by up to 70 %.

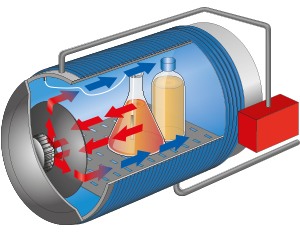

Radial fan

In combination with the optional sheathed cooling using cooling water and support pressure, the air circulation generated by a radial fan ensures faster re-cooling of the sterilization material.

The re-cooling time can then be reduced by up to 70 %.

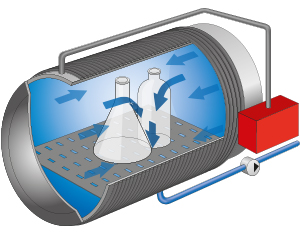

Ultra-cooler

When an ultra-cooler is used together with the sheathed cooling with cooling water and support pressure and the radial fan, the

Total re-cooling time is reduced by up to 90 %.

For Sterilizing Solids

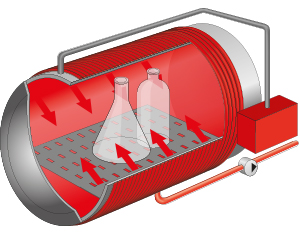

Vacuum device

The vacuum device generates a fractionated pre-vacuum. This de-aerates the solids and porous sterilized materials very effectively before they are sterilized using the standard built-in steam generator. This is mainly used for safely sterilizing materials such as tubes, hoses, textiles and even waste in destruction bags.

Superdry

The optional Superdry technology applies heat to the sterilized material through the steam generator for the external sterilization chamber heater. This makes the drying process much more efficient for porous and solid sterilization materials. By combining Superdry with the vacuum device, drying is optimized to such an extent that post-cooling in a drying oven is no longer necessary.

For Sterilizing Wastes

Vacuum device

The vacuum device generates a fractionated pre-vacuum. This de-aerates the solids and porous sterilized materials very effectively before they are sterilized using the standard built-in steam generator. This is mainly used for safely sterilizing materials such as tubes, hoses, textiles and even waste in destruction bags.

For the Sterilization of Biological Hazardous Materials

Exhaust air filtration

Systec autoclaves can optionally be fitted with exhaust air filtration. During the sterilization of biological hazardous substances, a filter cartridge (PTFE membrane with a pore size of 0.2 μm) ensures that the condensate remains in the pressure vessel during both the heating phase and the sterilization phase. The condensate and filter cartridge are automatically sterilized in-line during each sterilization process. A PT-100 temperature sensor is built in for this, ensuring that the optimum sterilization temperature is reached in the filter cartridge.

Your partner for autoclaves and sterilization processes.

Benefit from our extensive industry experience of more than 25 years.

Our team of sales, technical, installation and service experts will help you meet your sterilization needs.

Are you looking for smaller autoclaves or benchtop units? Here, we offer a large selection of autoclaves from 40 liters.